Wine is not only a cherished beverage enjoyed by millions around the world, but it is also one of the oldest fermented products with a rich history spanning millennia. The art of winemaking has evolved significantly over time, thanks to groundbreaking discoveries and advancements in microbiology. This informative blog post explores the pivotal role of microorganisms in wine production, the challenges they pose, and how the wine industry ensures quality control and spoilage prevention.

Microbiology's Role in Wine Production

Louis Pasteur, the renowned French chemist, and microbiologist, played a significant role in understanding the importance of microorganisms in wine production. In the mid-19th century, he not only confirmed the existence of microorganisms in wine but also shed light on their dual role in both the production and spoilage of wine. This discovery laid the foundation for modern winemaking practices.

Spoilage Microorganisms

One of the key challenges in the wine industry is the presence of spoilage microorganisms, which can negatively impact the taste, aroma, and overall quality of wine. Some of the main culprits responsible for spoilage include:

Wild Yeast Strains (Brettanomyces/Dekkera): These are troublesome yeast strains that can introduce off-flavors, such as a "barnyard" or "horse sweat" aroma, and alter the sensory characteristics of wine.

Acetobacter: These acetic acid bacteria can lead to the formation of acetic acid (vinegar), which is undesirable in wine.

Lactic Acid Bacteria (LAB): This group includes Acetobacter and Lactobacillus, which can cause undesirable changes in acidity, texture, and aroma in wine.

Critical Points of Microbiological Contamination

The wine industry recognizes several critical points where the risk of microbiological contamination is high. These include:

Quality of Raw Material: The quality of grapes used in winemaking is of paramount importance. Grapes may carry natural microbiota that can influence the fermentation process. Clean and healthy grapes are crucial to ensuring a successful fermentation.

Presence of Wild Yeast Strains During Fermentation: Uncontrolled fermentation can lead to the dominance of wild yeast strains, particularly Brettanomyces, which can introduce unwanted flavors and spoil the wine.

Wine Aging in Barrels: Wooden barrels, often used for aging, can harbor microorganisms if not properly sanitized. This can lead to spoilage and the development of undesirable characteristics in the wine.

Essential Microbiological Products for Quality Control in Winemaking

Winemaking is a delicate and intricate process that involves a myriad of factors, including the influence of microorganisms. To ensure that wines meet the highest standards of quality, winemakers employ various microbiological control techniques and products. In this section, we'll explore some of the key products used in the wine industry to address specific challenges related to acetic acid-resistant microorganisms, Brettanomyces/Dekkera spp., general spoilage microorganisms, and Lactobacillus spp.

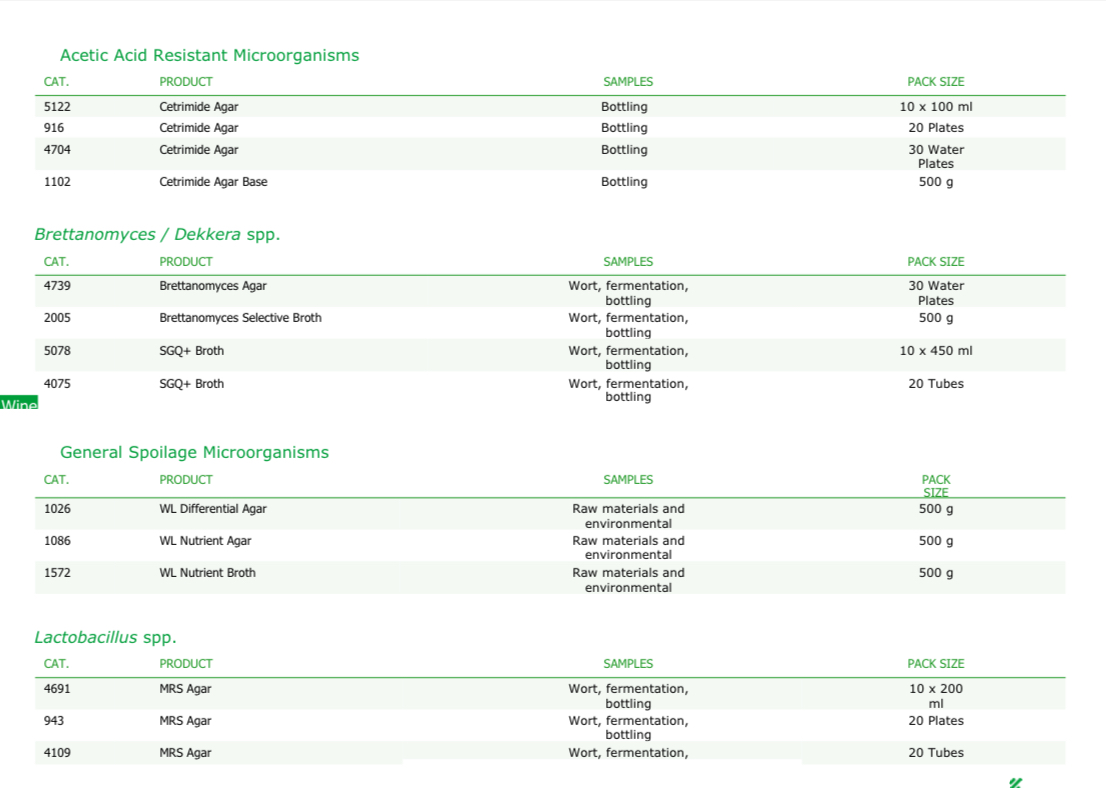

Acetic Acid Resistant Microorganisms

Acetic acid-resistant microorganisms pose a significant threat to wine quality. These microorganisms can lead to the unwanted formation of acetic acid (vinegar). To combat this issue, winemakers rely on specialized products, including:

Cetrimide Agar (CAT. 5122): Used in bottling processes, this agar medium is available in a pack size of 10 x 100 ml. It helps in the detection and control of acetic acid-resistant microorganisms.

Cetrimide Agar (CAT. 916): Also for bottling purposes, this product comes in a pack of 20 plates, providing ample resources for microbiological analysis.

Cetrimide Agar (CAT. 4704): Designed for bottling, this variant is offered in a pack of 30 water plates, making it suitable for larger-scale winemaking operations.

Cetrimide Agar Base (CAT. 1102): Available in a 500 g pack, this agar base serves as a fundamental tool in addressing acetic acid-resistant microorganisms during the bottling process.

Brettanomyces / Dekkera spp.

The presence of Brettanomyces/Dekkera spp. can lead to off-flavors and spoilage in wine. Winemakers use specific products to detect and manage these microorganisms, such as:

Brettanomyces Agar (CAT. 4739): Designed for use in wort, fermentation, and bottling, this product comes in a pack of 30 water plates, offering precision in detecting Brettanomyces.

Brettanomyces Selective Broth (CAT. 2005): Available in a 500 g pack, this selective broth aids in the identification and management of Brettanomyces spp. during various stages of winemaking.

SGQ+ Broth (CAT. 5078): Specifically tailored for wort, fermentation, and bottling processes, this product is available in a pack of 10 x 450 ml.

SGQ+ Broth (CAT. 4075): Similar to the previous product, this broth is supplied in a pack of 20 tubes, providing options for different winemaking operations.

General Spoilage Microorganisms

To address the broader spectrum of spoilage microorganisms, winemakers rely on specific products, including:

WL Differential Agar (CAT. 1026): Suitable for analyzing raw materials and the winemaking environment, this product is available in a 500 g pack.

WL Nutrient Agar (CAT. 1086): This nutrient agar is used for assessing raw materials and environmental factors in winemaking, provided in a 500 g pack.

WL Nutrient Broth (CAT. 1572): In a 500 g pack, this nutrient broth is essential for detecting and managing general spoilage microorganisms.

Lactobacillus spp.

Lactobacillus spp. can influence acidity, texture, and aroma in wine. To monitor and control their presence, winemakers turn to products like:

MRS Agar (CAT. 4691, 943, 4109): Available in various pack sizes, including 10 x 200 ml, 20 plates, and 20 tubes, MRS Agar is indispensable for detecting and managing Lactobacillus spp. during wort, fermentation, and bottling.

MRS Agar (CAT. 1043): A 500 g pack size of MRS Agar is also available, providing flexibility to winemakers.

MRS Agar Low pH (CAT. 4684, 1433): Designed for wort, fermentation, and bottling, this variant comes in pack sizes of 10 x 200 ml and 500 g.

Rogosa SL Agar (CAT. 1096): Offered in a 500 g pack, this agar is vital for detecting and controlling Lactobacillus spp. during winemaking.

International Methods of Analysis

To address these challenges, the International Organisation of Vine and Wine (OIV) has taken a proactive approach. They have created a compendium of international methods of analysis, which includes a dedicated section for microbiological control of wine and wort. These standardized methods help winemakers detect and mitigate the risks associated with spoilage microorganisms, ensuring the production of high-quality wines.

The wine industry's journey from ancient traditions to modern winemaking practices has been greatly influenced by our understanding of microbiology. The discovery of microorganisms in wine by Louis Pasteur and the ongoing efforts of organizations like the OIV have allowed winemakers to better control the quality of their products and prevent spoilage. With the right tools and knowledge, the industry continues to produce exquisite wines that delight connoisseurs worldwide.

References:

- Iland, Patrick, et al. "Microbiological Analysis of Grapes and Wine: Techniques and Concepts." Patrick Iland Wine Promotions Pty Ltd, 2012.

- Bisson, Linda F., and Peter A. Maga. "Brettanomyces Affect on Wine Quality and Detection." Wine Business Monthly, 1999.

- International Organisation of Vine and Wine (OIV). "Compendium of International Methods of Analysis of Wine and Musts." OIV Publication, 2017.

Zoey

Technical Sales Specialist at InnScience